Boost Efficiency: How a Simple Fix for Solar Conduit on Roof Works

Updated: 07 Sep 2024

18

Is there a solar conduit on roof that increases unexpected energy loss or inefficiency? A common mistake that most homeowners make is to ignore this aspect, which results in the poor performance of the solar panels. A wrongly conduit installed or a damaged conduit may cause considerable amounts of energy to be lost and possibly dangerous. To elaborate on this concept, let’s take a look at this article focusing on the importance of repairing a solar conduit on the roof to increase the effectiveness of the system. In this article are some useful tips on how to get the most out of your solar power investments and where to go from there.

The best way to run solar conduit on roof

The best way to run solar conduit is presented in the following ways.

The most appropriate procedure for running solar conduit is to use chases that follow eaves or valleys and this makes the installation rather invisible. Also, the proper color of conduit should be used and if possible, the conduit should be taken through the attic to reduce its outer exposure. Besides, this approach gives the conduit not only a more aesthetic look but also prevents its degradation due to weather conditions.

Conduit in the roof

This hypothesis is based on the fact that the leakage has been obvious in the roofs of the building which suggests that the building used to have some sort of conduit on the roof as specified in the designs.

Conduit in the roof is essential in ensuring proper protection of electrical wiring with a focus on solar panels. Installation of conduits also protects wires from any damages caused by physical factors such as moisture and very sharp temperatures that may hamper the efficiency of the system. Further, the wiring organization also contributes to roof structure stability and overall protection from possible failures with the help of conduits.

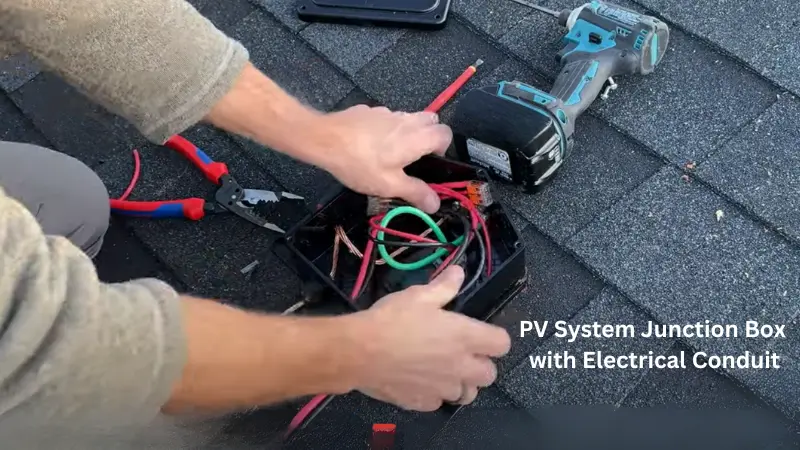

What Is Conduit in a Solar Energy System?

This is protective tubing along conductor pipes that contain electrical wires in a solar energy system linking the Solar Panels to the other devices like the inverters, or the electrical service panel among others. Conduits guarantee that the wires are secure from external vices and harm which would lead to the deterioration of the system in place. There are also two general categories which are rigid and flexible pallets and are made of metal or plastic.

During solar panels installation it is crucial to opt for the right type of conduit for electrical wiring and durability of the system. In solar installations, the two most common conduits are rigid and flexible conduits which are explained below.

Rigid Conduits:

Rigid conduits are usually constructed from metal or thick-walled plastics and shall be resistant to physical damage and can be applied where the conduit is exposed to the outside environment. They keep the wiring from harm’s way and also make the wiring more resistant to other conditions.

Flexible Conduits:

These are most suitable in areas that have many bends and corners, where rigid conduits cannot be successfully installed. These conduits are usually made out of plastic or metal and are preferred where there are bends or curves or in general; where flexibility of the conduit is desirable.

These come in both metallic and non-metallic varieties a choice about which will depend on the nature of the installation.

Solar Conduit Requirements

Solar conduit is a very important accessory for any solar power system since it is responsible for housing the conductors that link your solar power panels to either your inverter or your power grid. The immediate knowledge of the specific details of the conduit to be used in casing the solar cables goes a long way in eliminating any misunderstandings, delays, and increases in cost that extra conduit may bring along.

Material and Durability

The conduit must be of materials that are durable to accommodate different environmental factors such as UV radiation, variation in temperatures, and mechanical forces. These consist of PVC, EMT (Electrical Metallic Tubing), and rigid metal conduits, which are dissimilar in their sturdiness and pliability delivered by the surrounding circumstances of the installation.

Size and Capacity

Construction must be done in such a way that the number of wires as well as their gauges are properly managed. The conduit should not be too packed for they will heat up and probably cause some damage to the wiring. The NEC rules generally regulate the fill capacity of conduits concerning the safety measures that have to be adopted.

Installation Standards

Conduit installation is also required to adhere to local standards of the electrical codes since they contain information on how the conduit should be placed, anchored, and shielded. For instance, conduit placed on roofs has to be done in a manner that does not allow water into it and should be installed in an area where it will not be exposed to heat and thus expand.

Conclusion

Roof flashing is therefore very crucial for the normal functioning of any roofing project, and this is brought about by proper installation and maintenance of roof penetrations. Regarding correct sealing, usage of curbs for flat roofs, and inspection, it is possible to minimize leakage and other troubles. It is especially wise to hire a professional for the installation or modification of the floor to conform to the set building laws. Getting your roof ready for possible water damage and ensuring its efficiency plays a critical step in increasing the longevity of the roofing system in your house.

Please Write Your Comments